<>

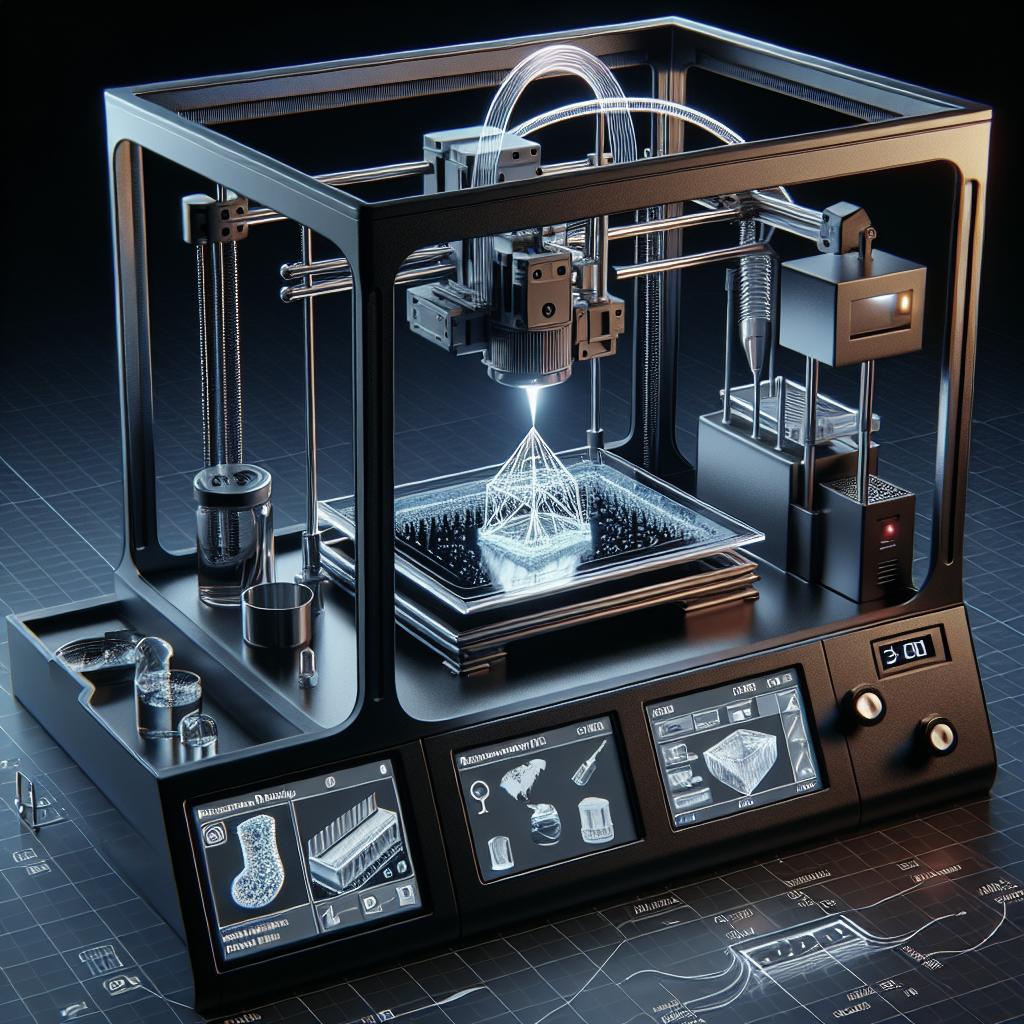

3D printing, once a mere speculative concept, has rapidly evolved into a groundbreaking technology transforming how items are manufactured. Jewelry design is no exception. Today, designers leverage 3D printing to create intricate, customized pieces that were previously thought impossible. With the ability to print in various precious and semi-precious metals, the world of 3D-printed jewelry opens endless possibilities for innovation and creative expression. In this blog post, we’ll explore the top four materials used for 3D printing jewelry: gold, silver, brass, and bronze. We’ll delve into each metal’s characteristics, advantages, and how they’re used in the jewelry-making process. Additionally, we’ll touch on other 3D printing materials suitable for jewelry and provide insights into what the future holds for this exciting intersection of technology and artistry.

Top Four 3D Printing Materials For Jewelry Designers: Gold, Silver, Brass, Bronze

As 3D printing technology advances, so does the variety of materials available for jewelry designers. Gold, silver, brass, and bronze stand out among the top choices due to their blend of aesthetic appeal and material properties. Each of these metals offers unique benefits, making them preferred options for different design preferences and functional needs. Let’s explore these top four materials in more detail, beginning with gold, the timeless symbol of luxury and tradition.

1. Gold

Gold has long been synonymous with opulence and elegance, making it a staple in jewelry design. With 3D printing, designers can push the boundaries of creativity by crafting intricate and complex gold pieces that would be labor-intensive to create using traditional methods. 3D printing in gold typically involves processes like Direct Metal Laser Sintering (DMLS) or wax casting, where the design is printed in wax and then cast in gold. The benefits of using 3D printing for gold jewelry are plentiful. Firstly, it allows for exceptional detailing, providing a level of precision that handcrafting can’t achieve. Secondly, it’s highly customizable, enabling designers to produce personalized pieces tailored to individual preferences. Whether it’s a custom engagement ring or an avant-garde statement necklace, 3D printing in gold caters to bespoke demands with ease.

2. Silver

Silver is another popular material in the world of 3D-printed jewelry. Known for its affordability and versatility, silver is suitable for a wide range of jewelry styles, from classic to contemporary. Like gold, silver can be printed using DMLS or wax casting methods, ensuring high-quality results. One of the key advantages of 3D printing silver jewelry is its ability to produce items with exquisite detail and complexity. This precision allows for the creation of intricate designs that stand out for their craftsmanship. Additionally, silver’s affordability compared to gold makes it an attractive option for designers and consumers alike, who seek high-quality, unique pieces without the premium price tag. 3D-printed silver jewelry also benefits from improved sustainability. Traditional silver mining and smithing can have significant environmental impacts, whereas 3D printing reduces material waste and energy consumption. This greener approach to jewelry making appeals to eco-conscious consumers looking for ethically produced accessories.

3. Brass

Brass, an alloy of copper and zinc, is prized for its bright, yellow-gold appearance and durability. It’s a cost-effective alternative to gold and is often used for creating bold, statement pieces. There are several finishes available for 3D-printed brass jewelry, including raw brass and coated versions.

Raw Brass

Raw brass is brass in its more natural state. It has an appealing, almost rustic look, which can develop a unique patina over time as it reacts with the environment. This characteristic makes raw brass a favored choice for vintage or antique-style jewelry designs. Additionally, raw brass is highly durable, ensuring longevity even with frequent wear.

Raw + PU Coated

To protect raw brass from tarnishing and ensure the longevity of the piece, a polyurethane (PU) coating can be applied. This transparent coating preserves the brass’s natural sheen and offers added protection against corrosion and wear. Jewelry designers favor this option for its balance between the natural aesthetic of raw brass and the practical benefits of added durability.

Polished Yellow-Gold Plating

For those seeking the luxurious look of gold without the associated cost, polished yellow-gold plating over brass is an excellent option. This process involves electroplating the brass piece with a thin layer of gold, delivering a shiny, gold-like finish. Polished yellow-gold plated brass jewelry offers an affordable way to enjoy the visual appeal of gold.

Polished Red-Gold Plating for Brass

Polished red-gold plating, or rose gold, is another popular finishing option for 3D-printed brass jewelry. The warm, reddish hue of rose gold is achieved by alloying gold with copper. This coating not only enhances the aesthetic appeal but also makes the piece stand out due to its distinctive color. Rose gold jewelry has a romantic and elegant flourish, making it ideal for special occasions.

Polish + Black Color Plating for Brass

Black-plated brass is ideal for creating edgy, contemporary jewelry. This modern finish involves electroplating polished brass with a black coating, resulting in a sleek, sophisticated look. Black-plated brass pieces are versatile and can be used for minimalist designs or bold, statement pieces, making them a trendy choice in modern jewelry design.

4. Bronze

Bronze, an alloy consisting primarily of copper and tin, is renowned for its rich, warm appearance and historical significance. It’s a durable material often used for creating timeless, intricately designed jewelry. Bronze is ideal for pieces that require a touch of vintage elegance with a classic appeal. One of the significant advantages of using bronze in 3D-printed jewelry is its patina. Over time, bronze develops a natural patina, giving each piece a unique, antique-like appearance. This evolving finish makes bronze a popular choice for designers aiming for a rustic or historical aesthetic. Additionally, bronze is relatively affordable, making it accessible for various market segments. Like brass, bronze can also be coated to prevent tarnishing and enhance durability. PU coatings and polishing techniques can be applied to maintain the metal’s luster and prolong the life of the jewelry. These protective measures ensure that bronze jewelry remains a cherished piece in anyone’s collection for years to come.

Other 3D Printing Materials for Jewelry

While gold, silver, brass, and bronze are the primary materials used in 3D printing jewelry, designers are also experimenting with other innovative materials. These alternatives offer unique properties and aesthetic possibilities, further expanding the horizons of 3D-printed jewelry. One such material is stainless steel. Valued for its strength and modern, industrial look, stainless steel is ideal for creating durable and robust jewelry pieces. Additionally, stainless steel can be polished to varying degrees of shine or left with a matte finish, providing versatility in design aesthetics. Another material gaining popularity is titanium. Known for its light weight and exceptional strength, titanium is perfect for those seeking hypoallergenic jewelry that’s also incredibly durable. Its sleek, modern appearance makes it a favorite for contemporary designs. Lastly, nylon, a flexible, lightweight plastic, is used to create vibrant, colorful jewelry. With 3D printing, nylon can be dyed in a myriad of colors, allowing for fun and playful designs that cater to fashion-forward individuals. Despite being a non-metal, nylon offers unique possibilities for creativity and expression in jewelry design.

Future Prospects

HTML table summarizing content: “`

| Material | Characteristics | Advantages | Finishing Options |

|---|---|---|---|

| Gold | Luxurious, elegant | Exceptional detailing, highly customizable | N/A |

| Silver | Affordable, versatile | Exquisite detail, improved sustainability | N/A |

| Brass | Bright yellow-gold appearance, durable | Cost-effective, variety of finishes | Raw, Raw + PU Coated, Polished Yellow-Gold Plating, Polished Red-Gold Plating, Polish + Black Color Plating |

| Bronze | Rich, warm appearance, historical | Develops unique patina, relatively affordable | PU coatings and polishing |

| Other Materials | Stainless Steel, Titanium, Nylon | Valued for strength, lightweight, vibrant colors | Polished, matte, dyed |

“` The fusion of 3D printing and jewelry design stands at the cutting edge of technological innovation, bringing unparalleled creativity and customization options to designers and consumers alike. As 3D printing technology continues to evolve, the materials available for jewelry making will undoubtedly expand, offering even more exciting possibilities for unique and sustainable designs. The future of luxury and fashion jewelry is poised for transformation, thanks to the limitless potential of 3D printing.